Large Capacity Dryers

CLM's reliable and durable large capacity dryers, including high-capacity dryers, provide high-end productivity and efficiency to help you make money over many years of operation through:

- Efficient heating

- High volume airflow

- Large baskets

- Long-life basket drives

- Revolving doors

- Basket design prevents damage to goods

- Industrial quality

- Precise operational controls

CLM’s high-efficiency dryers use a full flame spectrum modulating burner to precisely control fuel usage while maintaining optimal temperature set points. This design ensures rapid heat cycle termination, reducing overall fuel consumption and providing significant savings over time.

The high-volume dryers by CLM feature cross-axis airflow, ensuring uninterrupted jet streams of air across the entire drying area. This advanced airflow system guarantees quick and efficient water removal. The high-capacity dryers are equipped with a blower that delivers 15–30% greater air volume compared to other models, ensuring excellent air penetration into the load.

High productivity means more dried goods per year. It may also mean your business requires fewer dryers to do the same work than competitors’ models. Labor savings along with less overtime deliver more dollars to your bottom line.

CLM’s industrial dryers boast the largest basket capacity available in the market. The spacious design of these large capacity dryers ensures enhanced air access to the tumbling goods, resulting in faster, more even, and more efficient drying. The generous basket volume and diameter allow for the longest material drop possible, increasing interaction between heated air and goods.

Heavy-Duty Dryers with Long-Lasting Basket Drive

CLM’s unique basket drive system makes it easy to maintain.

The basket drive system in CLM’s heavy-duty dryers is designed for longevity. The main belt system maintains constant tension using a self-adjusting device, ensuring the v-belts are properly aligned. The high-strength main belt comes with a ten-year warranty when maintained appropriately. Optional features like soft-start basket rotation further enhance the durability of the drive components.

Long roller life means less downtime and reduced maintenance costs.

Unique to CLM’s high-capacity dryers, the revolving door seals directly to the rotating basket, eliminating product damage caused by gaps between the basket and the door. This design also minimizes downtime by eliminating the need for frequent seal adjustments or replacements.

Once the cycle is finished, the revolving door is lifted to the top of the dryer, leaving an unobstructed opening for dryer unload and load.

The heavy-duty dryers feature a robust drying basket with round perforations to prevent snags and damage to zippers or buttons. The lifting ribs are tall enough to provide proper material drop, but not so tall as to cause unwanted abuse to the drying products.

Our heavy duty drying basket is manufactured for long life. Round perforations help to prevent snags and damage to buttons and zippers. The lifting ribs are tall enough to provide proper material drop, but not so tall as to cause unwanted abuse to the drying products.

CLM offers removable basket panels standard on all machines.

These basket panels can be removed for ease in cleaning. And, extra panels can be purchased to limit downtime; just pop out the dirty panel and pop in the clean panel. Stainless steel material and smaller perforations are also available.

Optional Ceramic Coated Panels

This feature is enhanced by adding ceramic coating, which keeps plastics from sticking. It’s easy to clean and more durable than standard Teflon® coatings used on competitive models.

Removable ceramic coated panels make for easy cleaning and limit downtime.

While many competitive brands increased the size of their light gauge commercial machines to enter the industrial market, all CLM heavy-duty dryers are built with high strength materials and components to handle the stresses of industrial laundry processing. While commercial grade machinery may last 5-7 years, CLM’s equipment is built to last 2-3 times longer.

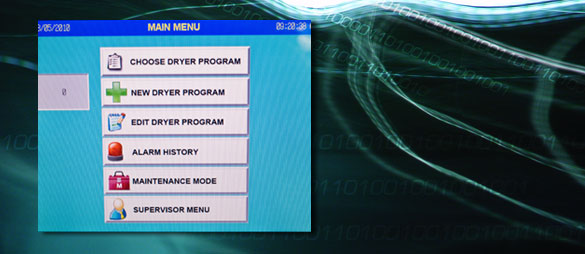

Control all aspects of the drying cycle with an easy-to-use touch screen display.

CLM’s high-efficiency dryers are equipped with the MicroCommand™ III PLC, a user-friendly control system with a colour touchscreen display. Ninety six user programmable formulas are available for you to control all aspects of dryer operation. Program it for standard full dry, conditioning, automatic full dry or automatic drying to a predetermined moisture level. Our inlet/outlet temperature algorithm helps take the guesswork out of heat cycle termination.

The MicroCommand™ III can also be programmed for optional automatic load and unload or for full automation with our industrial shuttles. It is self-diagnostic and instantly reports mechanical problems and any excessive down time. Basket rotation features are also controlled through the use of our component saving soft-start option and variable speed drive system that help the user determine the best material drop for each product (not available on all models).

Precise control of a modulating gas system is achieved through programming that is engineered to limit the amount of fuel used, while maintaining accurate temperatures (P.I.D. loop programming). This control commands a proven programming algorithm to terminate the heat cycle once the proper drying condition is reached.

CLM’s large capacity dryers, including high-volume dryers and high-efficiency dryers, are designed with you in mind. With features like long-lasting performance, precise controls, and minimal maintenance requirements, these machines deliver unmatched value to your business. At CLM, we take pride in our equipment and we stand behind it. Our products and services are second to none and our first responsibility is to you, our valued customer.